AfrahMarch 13, 2023

Assuring product quality is essential to business, particularly manufacturing. A product goes through various quality checks to ensure its excellence so that further adjustment is not required. Odoo quality module helps you to check your products quality in different operations.

Let’s see how we can use Odoo 16 quality module.

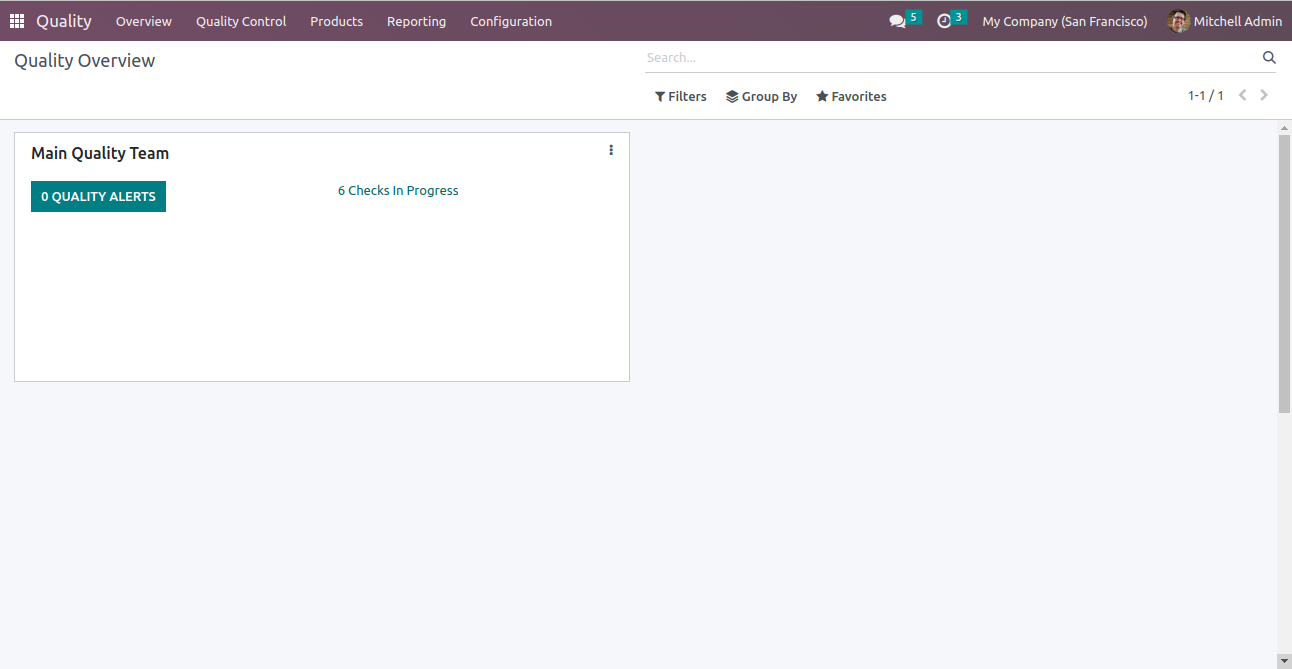

Quality Overview

Quality overview shows the Kanban view of quality teams, Each Kanban displays the count of checks in progress as well as quality alerts. We can create a new quality team from Quality team option in Configuration menu.

Quality Control

The quality control tab includes menus such as Quality Control Points, Quality Checks and Quality Alerts.

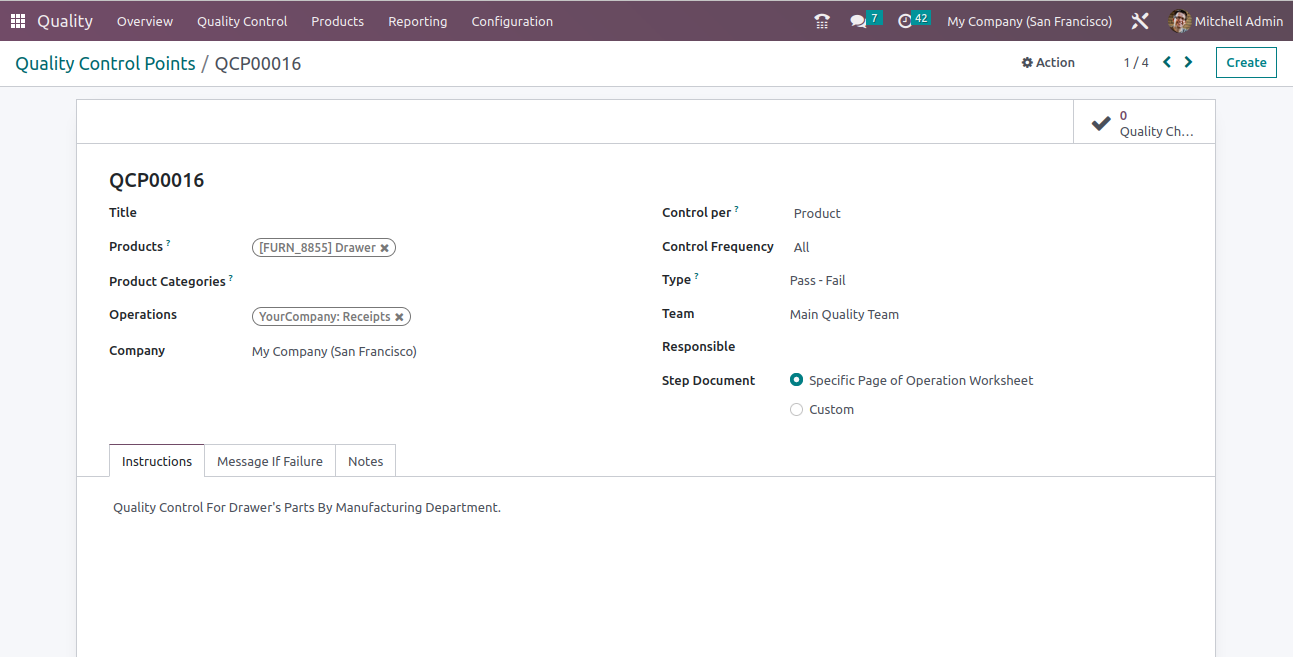

1. Quality Control Points

We can manage product quality easily using quality control points. Quality control point can be viewed as list view and Kanban view. Using Control points, We can define product and operation stages at which quality check should take place. Let’s check how to configure a Quality Control Point. To create a quality control point, select the create option in Quality Control Point menu

Title: The name of Control Point.

Products: Select the product on which quality control should be applied.

Product Categories: Select the product categories on which the quality point needs to be applied.

Operations: Select the stage on which the quality point needs to be applied. We can select multiple operations such as Receipts, Delivery, Manufacturing, etc.

Control per: Select the level such as Operation, Product, or Quantity on which quality check must be applied.

Control Frequency: Defines the intervals for quality checks such as All, Randomly, or Periodically. If randomly selected then we can define the percentage of production. If we selected periodically then we can specify frequency of days at which quality has to be checked.

Type: Type refers the type of quality point. It can be pass-fail, Instructions, Take a picture, or Measure.

Team: Team in charge of the control point.

Responsible: Here we can define the responsible person for the control point.

Step Document: Set the step document as either custom or specific page of operation worksheet.

Message if failure: We can define messages to be displayed if quality check fails.

Notes: Mention why we need to perform the quality check.

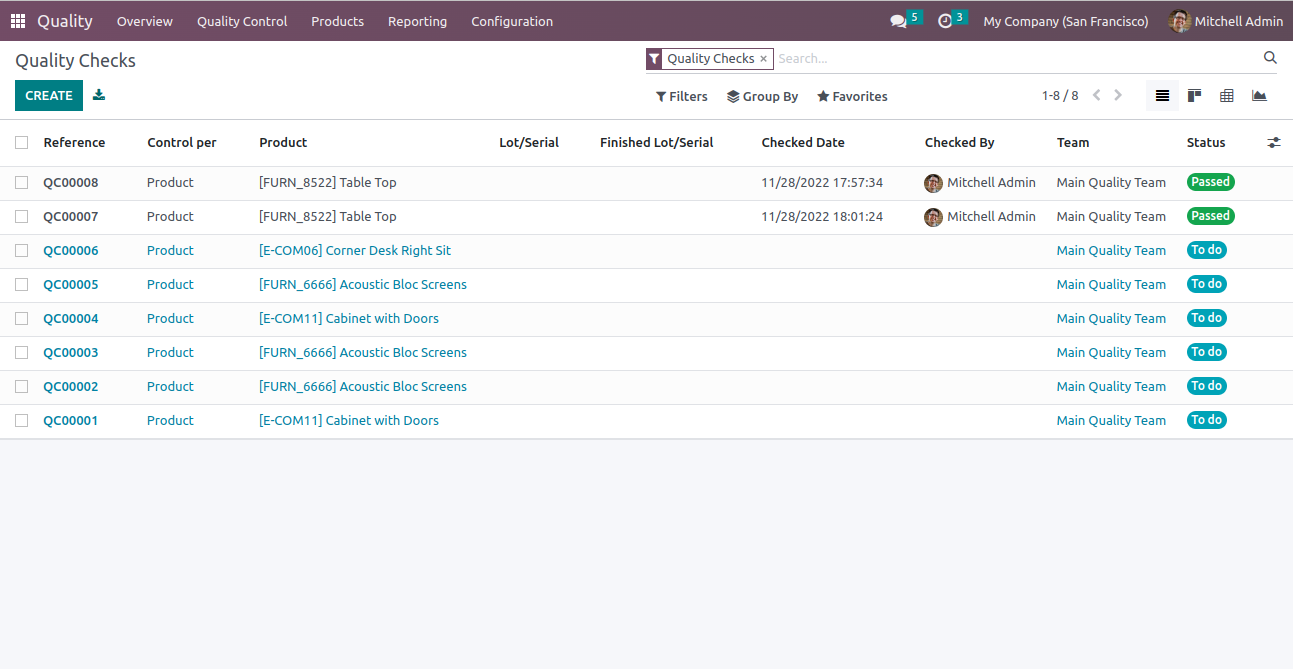

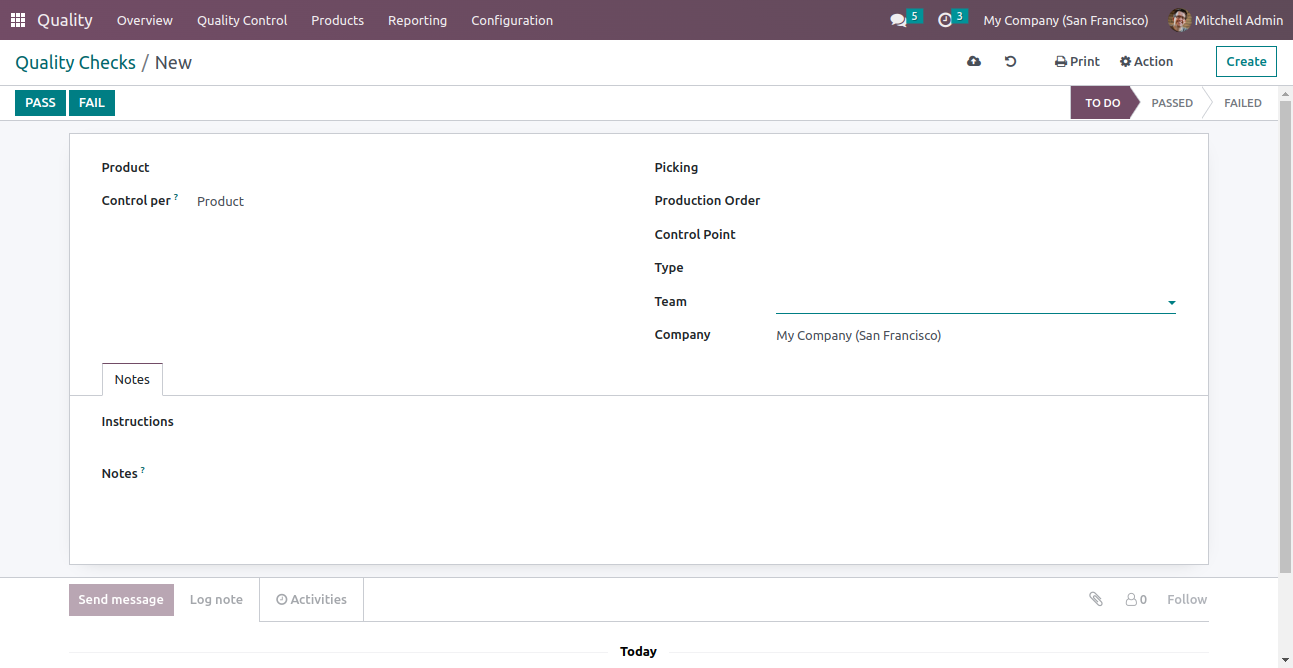

Quality Checks

Quality checks are automatically created and listed in the Quality Check menu when quality control points are defined. Utilizing quality checks, Operations in manufacturing and transfer order are generated.

Quality Check tree view consist of check Reference number, Product name, Checked date, Checked person, Quality team and Status of the check. We can create a new Quality Check using create button.

We can select picking, production order, control point, type and quality team for quality check while creating quality check directly. Using the PASS and FAIL buttons at the top, we can also manually select whether the product's quality check was successful or unsuccessful.

Quality Alerts

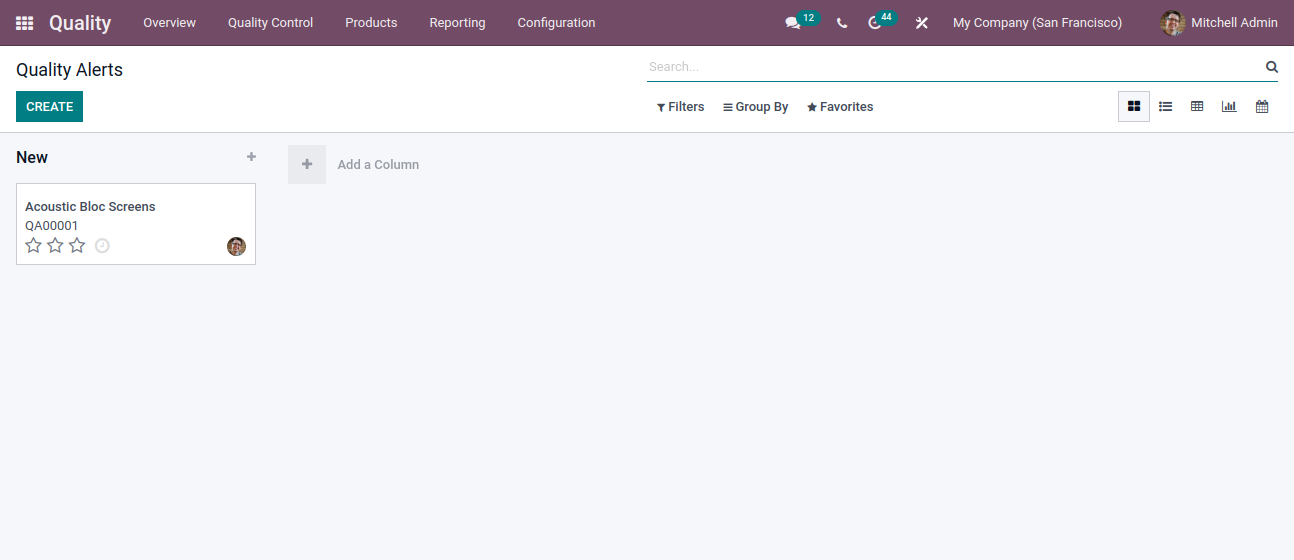

Using Quality alerts, we can remind the responsible employee about the quality check of product or service. Quality Alerts can be viewed in list, Kanban, calendar or pivotal form view but by default it is showed as Kanban view.

We can create a new quality alert by clicking on create button in the top. We can also develop a new stage by clicking on Add a column menu.

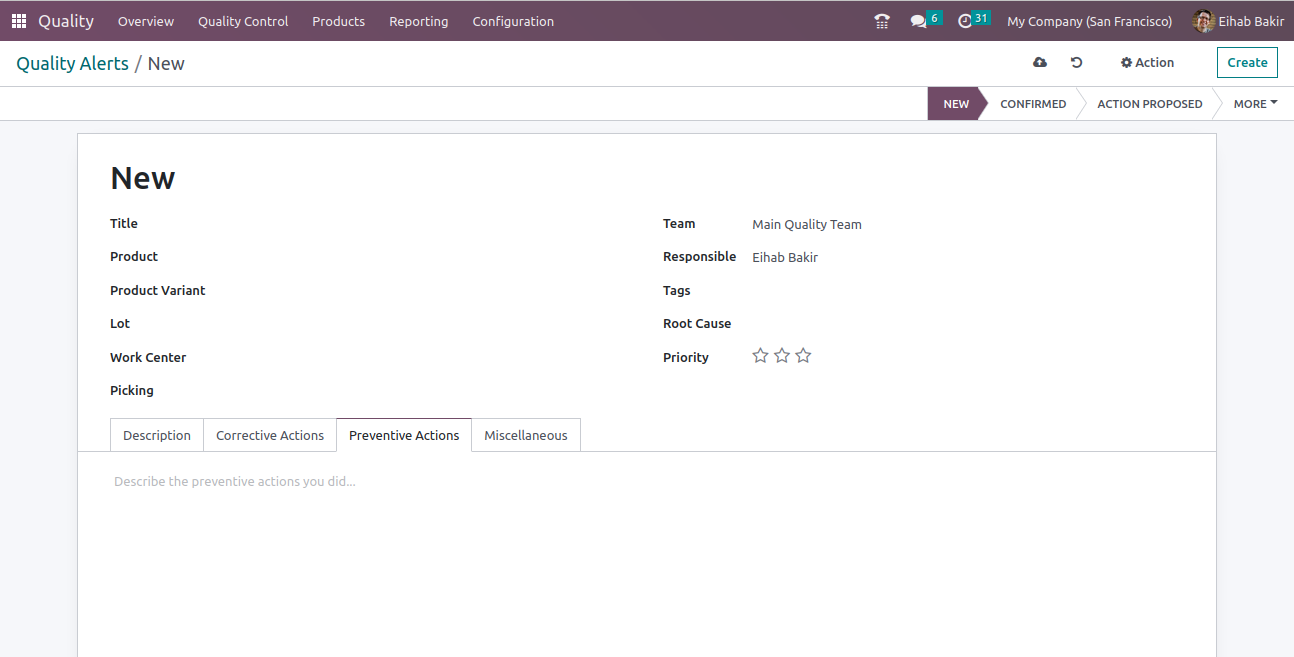

On creating a new alert we can define the title, product, product variant, lot, work centre where the quality equipment is situated, picking such as the warehouse of the product, Team, Responsible person for the quality alert, Tags if any , Root cause which can be WorkCentre failure, parts quality, work operation, or any other cause, we can also specify the priority of problem.

We can add the root cause of problem if any in the description tab given in the quality alert form. We can also add actions to correct the problem in corrective actions tab. The actions for preventing such problems can be mentioned in the preventive actions of the form. If we want to add any other details regarding the alert, we can add it in the miscellaneous tab.

Products And Lot/Serial Numbers

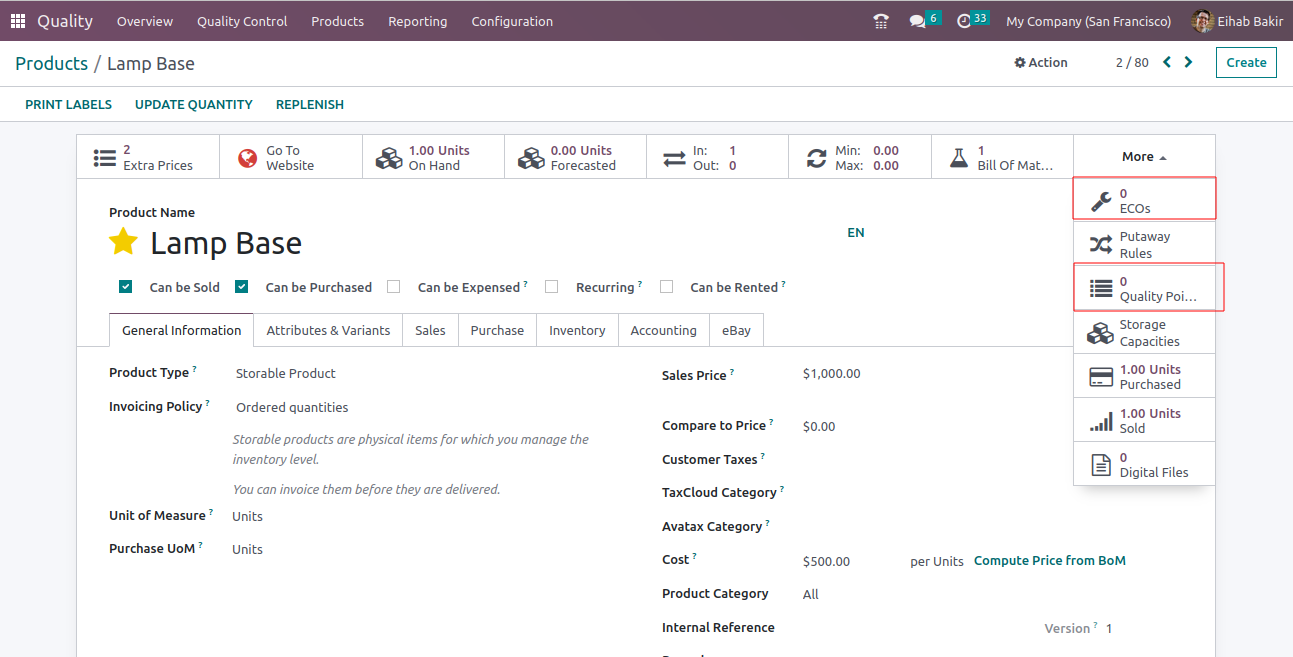

As in other modules like sales and purchase we can access product, product variant and lot/serial number from quality module. We can check the ECOs and Quality point of each product by selecting the product. ECOs and Quality points are shown as smart buttons in the product profile.

Reports

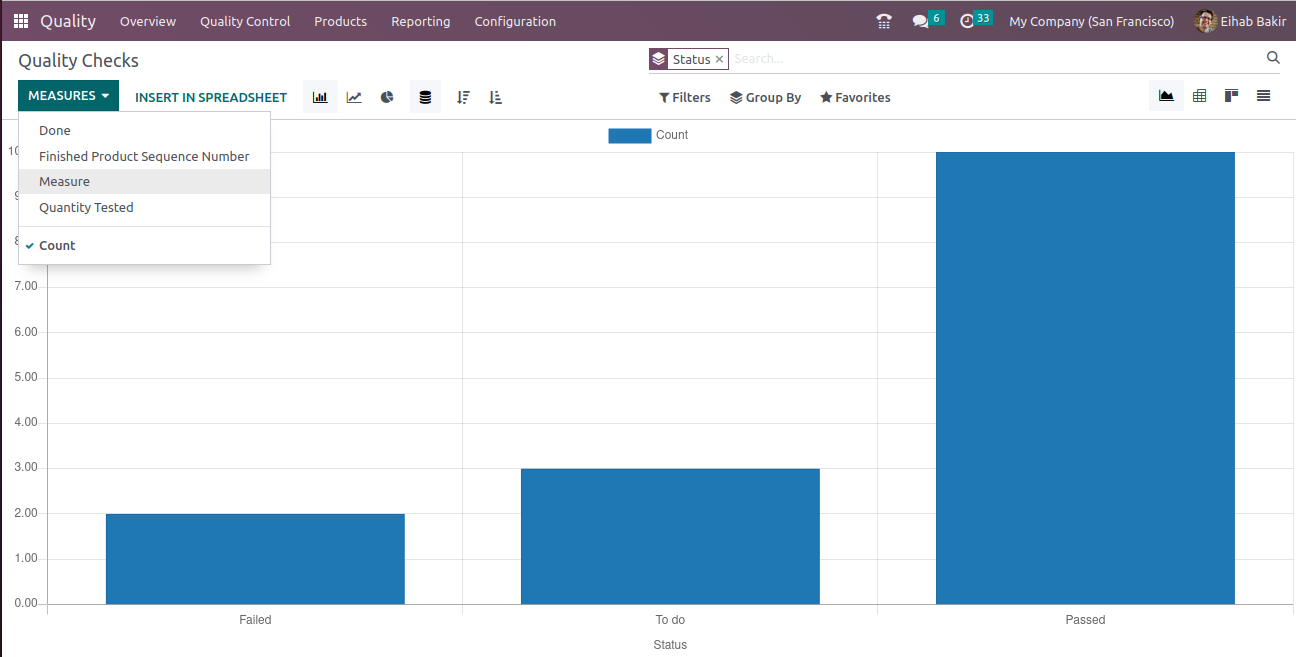

Odoo provides Quality Checks and Quality Alerts reports in quality module. Reports can be accessed from the Reporting menu. The Quality check report is by default based on the count. We can also add the measures such as Done, Finished Product Sequence Number, Measure, Quantity Tested.

In case of Quality Alerts, the report is based on the root cause of the problem and we can group it by Stage, Responsible, Root Cause, Creation date and Team.

0